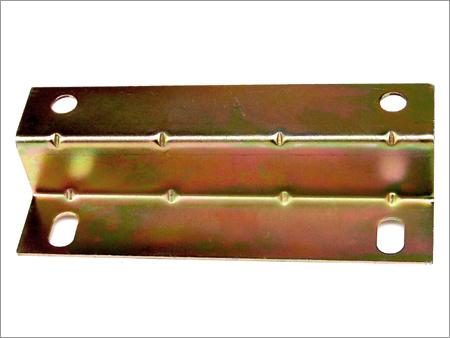

Z Type transformer Clamps

Z Type transformer Clamps Specification

- Weight

- 0.5 kg to 3 kg

- Metal Type

- Mild Steel

- Material Grade

- IS 2062 Grade A

- Density

- 7.85 Gram per cubic centimeter(g/cm3)

- Material

- Galvanized Steel

- Structure

- Z Type

- Standard

- IS 2062 / JIS / ASTM

- Shape

- Z Shape

Z Type transformer Clamps Trade Information

- Supply Ability

- Piece

- Delivery Time

- 24 Hours

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Z Type transformer Clamps

Slim Fittings Z-Type Clamps

Blessed & supported by the team of adroit professionals, our company is considered as one of the eminent manufacturers of Slim Fittings Z-Type Clamps. Our offered Z-type clamps find huge application in transformers. The clamps offered by us are highly reckoned in the market for their significant features such as resistance to corrosion, excellent durability and dimensional accuracy. We are offering these Slim Fittings Z-Type Clamps to our clients at cost effective prices.

Specification

- Material: Fresh CRC Sheets

- Sizes: Core Sizes

- Mounting: Vertical

- Thickness: From .45mm To .80mm

- Coating: Zinc Plating/ Powder Coated

- Application: Used for Standing Transformers

Built to International Standards

Z Type transformer clamps are manufactured in accordance with IS 2062, JIS, and ASTM standards, ensuring consistent quality and performance. The use of IS 2062 Grade A mild steel guarantees superior strength, while rigorous processes maintain uniformity across batches, making them ideal for critical electrical applications.

Corrosion-Resistant and Durable

Galvanized steel construction bestows these Z Type clamps with exceptional resistance to rust and corrosion. This ensures longevity and reliability even in challenging environments, providing peace of mind for users who require dependable components for electrical assembly tasks.

FAQs of Z Type transformer Clamps:

Q: How are Z Type transformer clamps typically used in transformer assembly?

A: Z Type transformer clamps are primarily used to secure the core laminations and maintain the structural integrity of transformers during operation. Their unique Z shape allows for effective distribution of mechanical load and minimizes movement, ensuring stability within the electrical assembly.Q: What benefits does galvanized mild steel offer for these transformer clamps?

A: Galvanized mild steel offers excellent protection against rust and corrosion, which enhances the lifespan and performance of the clamps. This makes them particularly suitable for environments where they may be exposed to moisture or varying temperatures.Q: When should Z Type transformer clamps be chosen over other clamp types?

A: Z Type clamps are ideal when specific structural reinforcement is needed for transformer cores, especially in situations demanding high-strength, reliable fasteners that comply with rigorous standards like IS 2062, JIS, or ASTM.Q: Where are these Z Type clamps commonly sourced and supplied in India?

A: These clamps are widely manufactured, supplied, and traded by reputable companies in India. Industrial hubs and electrical hardware markets across the country, particularly in regions with strong transformer manufacturing sectors, serve as typical sourcing points.Q: What is the standard manufacturing process for Z Type transformer clamps?

A: The manufacturing process involves cutting mild steel to shape, forming the Z structure as per design specifications, and then galvanizing the clamps for protection. Quality checks are performed to ensure adherence to IS 2062 Grade A and other applicable standards.Q: How do you determine the appropriate clamp weight for your requirement?

A: Choosing the correct clamp weight, ranging from 0.5 kg to 3 kg, depends on the size and design load of the transformer assembly. Consulting with the manufacturer or referencing technical specifications will help ensure a suitable match for your project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Clamp Category

Transformers Z Type Clamps

Minimum Order Quantity : As per the Product Piece

Material : Other, Galvanized Steel

Material Grade : IS 2062 E250

Density : 7.85 Gram per cubic centimeter(g/cm3)

Weight : According to size and thickness

Structure : Others, Z Type

Industrial Z Type Clamps

Minimum Order Quantity : As per the Product Piece

Material : Other, Mild Steel

Material Grade : IS 2062 E250

Density : 7.85 Gram per cubic centimeter(g/cm3)

Weight : Depending on size (Customizable)

Structure : Others, Z Type

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry